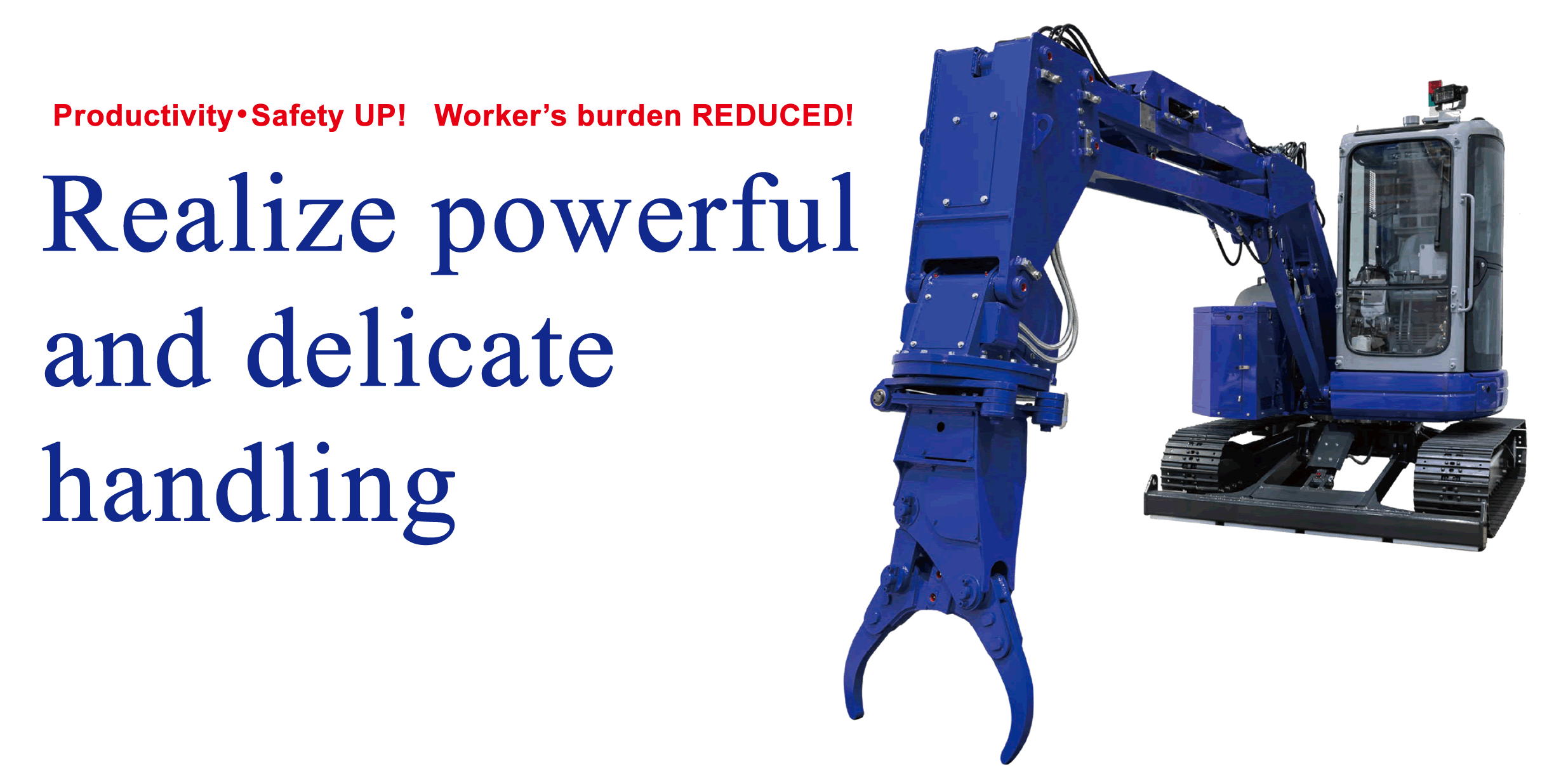

Self-propelled manipulator

Bi-Master

RAM700-5

Bi-Master was developed to reduce the burden on workers in processes including heavy, hot, and dangerous work, such as the casting frame removal process. It provides powerful support when transporting, moving, loading and unloading, or turning over heavy objects to meet the workplace need for greater productivity and safety.

For InquiriesBi-Master Features

1

Simple operation provides excellent operability

Bi-Master uses the bilateral master-slave method. A variety of arm movements can be controlled using just one lever giving operations the feel of being an extension of the operator’s arm. Good at powerful yet fine movement, Bi-Master can easily hang castings on moving conveyor hangers and perform palletizing work.

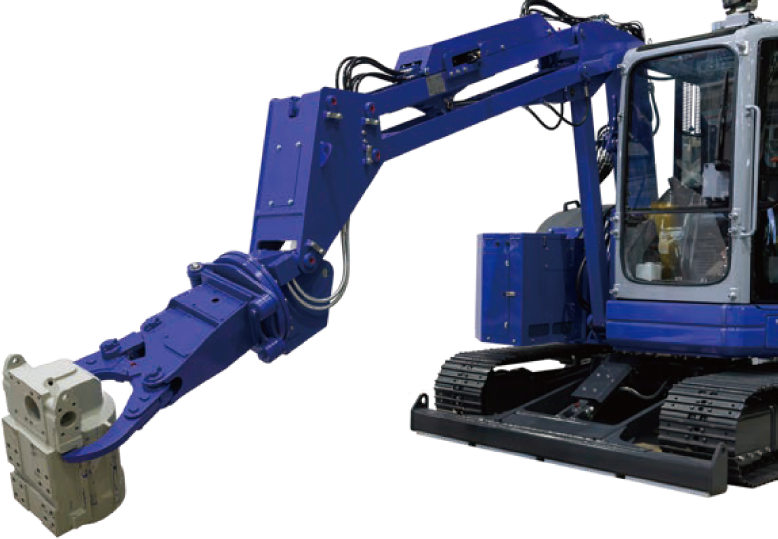

Hanging

Accurate parallel arm movement is useful for hanging objects on hangers.

Cabin

The cabin is equipped with functions that feed back operation reactions to the operator to even make it possible to build remote operation systems.

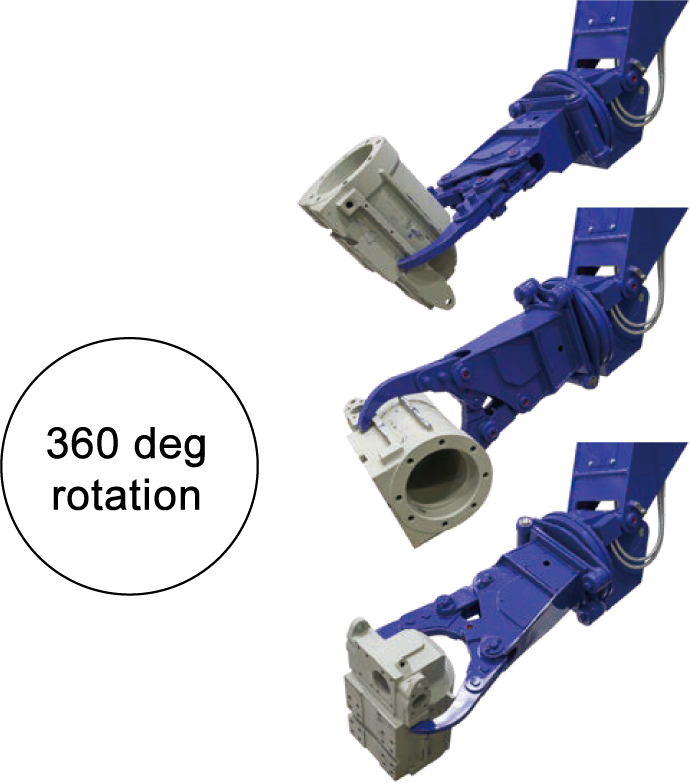

Object rotation

Heavy objects are easily turned over.

2

Self-propelled with a high degree of freedom

Unlike stationary equipment, the Bi-Master can move to where it is needed when it is needed. It flexibly responds to production line and production plan changes to support high-mix, low-volume production.

3

Clean electric drive system

No emission of exhaust gases maintains a clean work environment. A major advantage is less running cost than engine powered equipment.

Main Specifications

| RAM700-5 | ||

|---|---|---|

| Tight Turning Specifications | Improved Maintainability Specifications (Easy access to the electric motor, pump, and valves) |

|

| Model | Bilateral master-slave type operation manipulator | |

| Construction | Self-propelled dust-proof construction articulated manipulator (with integrated rubber shoe drive mechanism) | |

| Body weight | Approx. 5,400 kg | |

| Degree of freedom: Arm | 3 degrees of freedom (turning, vertical arm, horizontal arm) | |

| : Wrist | 2 degrees of freedom: (Vertical, rotating) | |

| : Hand | 1 degree of freedom (open/close) | |

| Control method | Electro-hydraulic servo | |

| Power | 3-Phase AC motor fully closed external fan 22 kW 200V 50 Hz / 200-220V 60 Hz | |

| Cabin | Dust-proof sealed box construction (with air conditioner for cooling and heating) | Outside air induction dust-proof sealed box construction (without air conditioner) |

| Max. transportable load | Max. 400 kg | |

| Hand gripping force | Max. 300 kg | |

| Hydraulic fluid cooling method | Air cooled | Water cooled |

| Control panel installation position | Mounted outside cabin rear | |

| Power cable | Approx. 15 m length 22 mm2 4-core cabtyre cable *1 | |

| Operation speed | ||

| Traveling (max. speed) | 4.0 km/h | |

| Body turning (max. speed) | 60 deg/sec | |

| Vertical arm | 1 m/sec | |

| Horizontal arm | 1 m/sec | |

| Wrist vertical | 30 deg/sec | |

| Hand rotation | 40 deg/sec | |

| Hand open/close (standard) | 15 deg/sec | |

| Operation range | ||

| Body turning | Max. 360 deg (Limited by power cable, etc.) | |

| Turning radius | Tight Turning Specifications 1,035 mm | Maintainability Improvement Specifications 1,495 mm |

| Vertical arm | 80 deg | |

| Horizontal arm | 110 deg | |

| Wrist vertical | 110 deg | |

| Hand rotation | 360 deg | |

| Hand open/close (claw tip stroke) | 0 to 520 mm | |

Bi-Master trademark registration pending.

●This product may be changed without notice to make improvements.

Bi-Master

RAM2200-7

Main Specifications

| RAM2200-7 | ||

|---|---|---|

| Model | Bilateral Master-Slave Type Operation Manipulator | |

| Construction | Self-propelled dust-proof construction articulated manipulator (iron shoe crawler type undercarriage) | |

| Body weight | Approx. 12,500 kg | |

| Degrees of freedom | : Arm | 3 degrees of freedom (turning, vertical arm, horizontal arm) |

| : Wrist | 2 degrees of freedom: (Vertical, rotating) | |

| Hand | 1 degree of freedom (open/close) | |

| Control method | Electro-hydraulic servo | |

| Power | 3-Phase AC motor fully closed external fan 55kW 400V 50Hz / 400-440V 60Hz | |

| Cabin | External air induction dust-proof sealed box construction (with cooler, electric heater) | |

| Max. transportable load | Max. 1,500 kg | |

| Hand gripping force | Max. 2,000 kg | |

| Hydraulic fluid cooling method | Water cooled (Customer supplies the cooling water) | |

| Control panel installation position | Mounted in cabin rear | |

| Power cable | Approx. 20 m length 60 mm2 4-core cabtyre cable | |

| Operation speed | ||

| Traveling (max. speed) | 4.0 km/h | |

| Body turning (max. speed) | 50 deg/sec | |

| Vertical arm | 0.8 m/sec | |

| Horizontal arm | 0.8 m/sec | |

| Wrist vertical | 30 deg/sec | |

| Hand rotation | 70 deg/sec | |

| Hand open/close (standard) | 15 deg/sec | |

| Operation range | ||

| Body rotation | Max. 360 deg (Limited by power cable, etc.) | |

| Turning radius | 1,480 deg | |

| Vertical arm | 80 deg | |

| Horizontal arm | 110 deg | |

| Wrist vertical | 110 deg | |

| Hand rotation | 360 deg (endless) | |

| Hand open/close (claw tip stroke) | 0 to 430 mm | |

| Hand tip max. reach distance | Approx. 4,500 mm | |

| Arm tip max. reach height | Approx. 4,400 mm | |

Bi-Master trademark registration pending.

●This product may be changed without notice to make improvements.